Ultrasonic Plastic Welding Machine Plastic Plugs Electronic Parts Welding

Overview Ultrasonic plastic welding machine Product Description Application: Widely used in aviation, boats, cars, elect

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | HY-2615 |

| Transport Package | Wooden Case |

| Trademark | HIPOWER |

| Origin | China |

| HS Code | 8515800090 |

| Production Capacity | 5000 |

Product Description

Ultrasonic plastic welding machineProduct Description

Application:

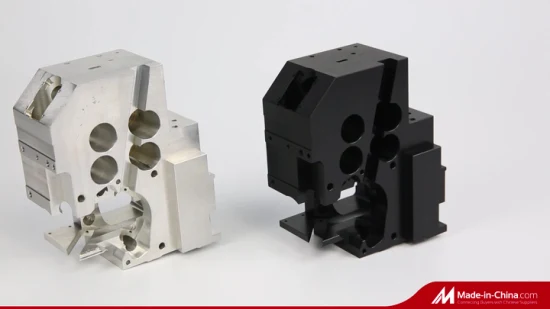

Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc. For example: disposable transfusion filter, blood plasma whizzer, valve bag, plastic wine bottle cap, dish washer waterwheel, plastic toys, car lamp,plastic fake bait, charger shell and mobile hanging drop welding, disposable lighter shell welding etc. Besides: car door plaque welding, car motormeter welding, car lamp car mirror welding, sun visor welding, car inside accessories welding.Apply for ABS, PE, PC, PS, PVC, PP, ABS & PC complex, Acrylic etc. materials.

Industrial Fields Applied :

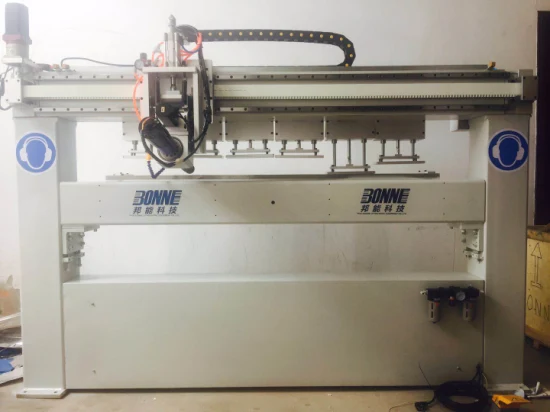

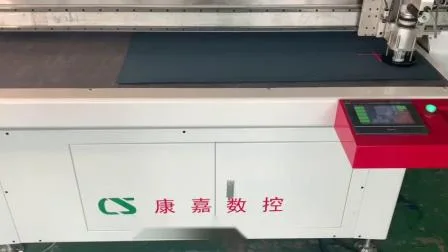

The straight line guide bearing, the precise matching device.The horizontal zoom type structures of four corners allocate that the board four corners at bottom can transfer the standard. Japan Huang Paigang becomes a ware, and the horizontal zoom type structure of lasting durable horn allocates that the board four corners at bottom can dive flatly

Machine General Features:

CE certificate

Auto tuning function available

15KHZ, 20KHZ, 28KHZ, 35KHZ

500W 800W 1500W 2000W 2600W 3200W 4200W available

| Model | HC-2615 | HC-1520 | HC-3215 | HC-4215 |

| Voltage | 220V | 220V | 220V | 220V |

| Pneumatic range | 2-7bar | 2-7bar | 2-7bar | 2-7bar |

| Frequency | 15KHz | 15KHz | 15KHz | 15KHz |

| Output POWER | 2600W/15KHz | 1500W/20KHz | 3200W/15KHz | 4200W/15KHz |

| Vibrational System | Auto-stimulating | Auto-stimulating | Auto-stimulating | Auto-stimulating |

| Auto Tuning | available | available | available | available |

| Prodcution speed | 2-5sec/pc | 2-5sec/pc | 2-5sec/pc | 2-5sec/pc |

| Air Compressor | 1HP to 2HP | 1HP to 2HP | 1HP to 2HP | 1HP to 2HP |

| Net Weight | 110KG to 115KG | 110KG to 115KG | 600KG | 600KG |

Who We Are:Since 2000, Shenzhen Hipower Ltd, concentrates on highest quality, on-time delivery, professional technology support,customer-oriented service and competitive price.Where Are our Customers:Our products are mainly exported to Asia, North America, South America, Europe and Africa, and etc....What we do:Our equipments are widely used in industrial application like: Automotive Parts, Stationery, conveyor belts Tarpaulin, BigCovers,Tents products, Tensile structure, Medical Bags, Blister Packaging, Cylindrical Box, and other plastic welding industries.

CertificationsPackaging & Shipping Our AdvantagesHipower is at the forefront of newest technical developments in the field of high frequency and ultrasonic welding

technology, automation of production processes, and other innovative industrial solutions.

a) Customer's site installation, training & maintenance available

b) 3 to 24 hours Online service by Email, Fax, Video Online for basic setup and repairs

c) 12 months warranty for machine, life-long tech. support

d) Recommend equipment of top choice based on your requirements for product;

e) Examining mold drawings on your behalf to confirm optimum structure size meeting the requested process;

f) Providing assistance in manufacturing and modifying tools;

g) Our engineering instruction will guarantee your productive manufacturing of top-quality products.

Questions 02: What about Delivery Time:RE: 3 days for standard machine; and 15 to 35 days for custom machines

Questions 03: Payment Term:RE: We accept payment by T/T, L/C, West Union, Paypal.

Questions 04: How do I inspect your machine quality?RE: We always have real machines ready in stock, We shall meet you at airport, hotel, or railway station.

Questions 05: Is the machine easy to use and maintain in future?RE: Yes, it is; we shall provide instructional manual, videos and engineer support via email or video talk online.

Questions 06. How Do You Pack the machinesRE: Our machines will be packed into after treatment wood boxQuestions 07. Does the machine power voltage meet buyers' factory power source?RE:Frequency: 50 - 60HZ Phases: single phase / 3 phases ; Voltage: 110V / 220V / 380V/ 415V/ 440V / On requestQuestions 9. Could you make die / mould for me, if I buy machine from you?RE: We design and make moulds up to product sample or drawings, we charge the mould price at facory cost price.

Related Products

-

![Not N95 Face Mask Making Servo Type Blow Molding Bottle Viscous Epidemic Use Liquid Gel Hand Sanitizer Disinfectant Soap Automatic Filling Machine]()

Not N95 Face Mask Making Servo Type Blow Molding Bottle Viscous Epidemic Use Liquid Gel Hand Sanitizer Disinfectant Soap Automatic Filling Machine

-

![Pet EVA Vinyl film Tape Nylon Leather Belt Sheet Tape Ear Loop Computer Cutting Machine]()

Pet EVA Vinyl film Tape Nylon Leather Belt Sheet Tape Ear Loop Computer Cutting Machine

-

![Automatic N95 Surgical Solid Face Mask Making Machine]()

Automatic N95 Surgical Solid Face Mask Making Machine

-

![Non-Woven Face Mask Machine Full-Automatic N95 Face Mask Making Machine]()

Non-Woven Face Mask Machine Full-Automatic N95 Face Mask Making Machine