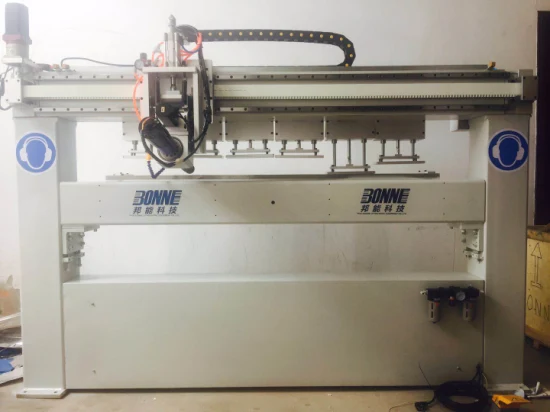

150-400GSM Ultrasonic Fabric Cutting Machine Used for Circular Looms

28kHz Ultrasonic fabric cutting machine Our factory is always focusing on designing and manufacturing cutting and weldin

Send your inquiryDESCRIPTION

Basic Info

| Max Rating Power | 800W |

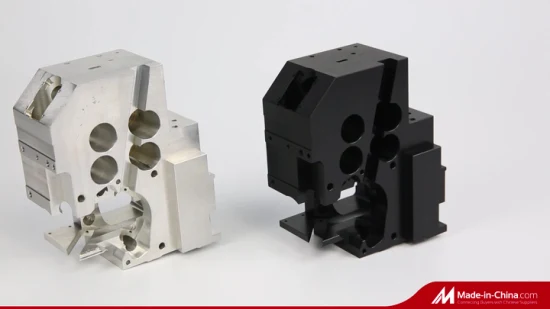

| Matching Transducer | Lk28-H38-Z4 |

| Cutting Value Range of Container Bag | 50-300g |

| Humidity | Less Than or Equal To85% Rh |

| Ambient Temperature | 0-40degree |

| Suitable for | Plastic, Rubber, Copper |

| Condition | New |

| CNC or Not | Yes |

| Cooling Mode | Air Cooling |

| Cutting Speed | 50cm/S |

| Transport Package | Wooden Case |

| Trademark | OEM |

| Origin | Xuzhou, China |

| HS Code | 84515000 |

| Production Capacity | 500set/Month |

Product Description

28kHz Ultrasonic fabric cutting machine

Our factory is always focusing on designing and manufacturing cutting and welding Ultrasonic equipment intended mainly for Geotextiles,technical textiles and FIBC/Jumbo bag/Hdpe Woven sac Industries.

The ultrasonic generator produce the mechanical energy of vibration more than 20000 times-400000 times per second to the cutting blade, it cut the material by local heating melt, to achieve the aim of cutting materials.

Specification

| Working power:220V-240V,50HZ-60HZ,5A |

| Max rating power:800 w |

| Matching transducer:LK28-H38-Z4 |

| Frequency tracking range:28KHz±400Hz |

| Working condition |

| Indoor use, humidity≤ 85% RH; ambient temperature: 0-40 ºC |

| There should be sufficient space around the machine, no less than 150 mm, to facilitate heat dissipation |

| Cutting value range of container bag: 50-300g |

Advantage

1. Good cutting effect, good smooth cutting edge and no rough selvedge (loose edge)

2. Cutting speed, reduce the staff's working intensity, cost savings

3. Simple operation, easy to install on machine

4. Precise cutting force control

5. Cooling system ensure it can work efficiently for a long time

Application

Ultrasonic Cutting Machine (cutter) is suitable for plastic woven rice bag fabric , PP jumbo bag,bulk sack,container bag,FIBC bag ,polypropylene woven bag fabric etc.

Our Service1. Training of equipment maintenance and operating personally.2.Installation and commissioning of equipment until everything is functional.3. One year warranty and Providing long-term maintenance service and spare parts.4. Giving technical support to customer for developing new product.5. Engineers available to service machinery overseas.6. Provide English Version of Installation/Operation/Service/Maintenance Manual.PackageSmall parts are packed in cartons and put in wooden cases.