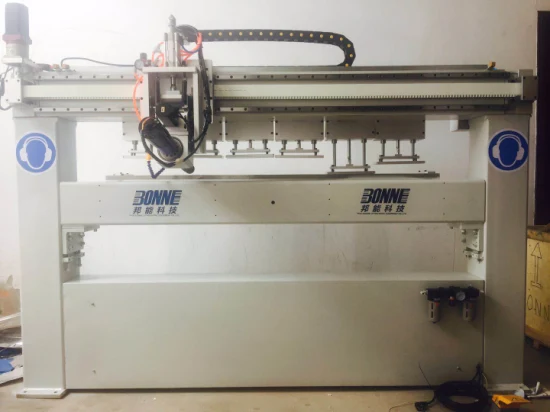

Automotive Ultrasonic Plastic Welding Sealing System of Stop Backlight Module

Overview Package size per unit product 80.00cm * 50.00cm * 60.00cm Gross weight per unit product 35.000kg Automotive Ult

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | H-UW20 |

| Frequency | 20kHz |

| Output Power | 2000watt |

| Horn Size | 110*20mm |

| Horn Material | Steel (SKD11/ DC53) |

| Warranty | 1 Year |

| Delivery Time | 10 Working Days |

| Transport Package | Wooden Case |

| Specification | 350(L)*310(W)*150(H) mm |

| Trademark | Hanstyle |

| Origin | China |

| HS Code | 8543709990 |

| Production Capacity | 5000/Year |

Packaging & Delivery

Package size per unit product 80.00cm * 50.00cm * 60.00cm Gross weight per unit product 35.000kgProduct Description

Automotive Ultrasonic Plastic Welding Sealing System of Stop Backlight ModuleProduct Description

Ultrasonic welding is the principle of fusion between the surfaces of two objects to be welded to form molecular layers by friction with each other. Ultrasonic welding is the conversion of 50/60 Hz current into 15, 20, 30 or 40 KHz electrical energy by means of an ultrasonic generator. The converted high-frequency electrical energy is again converted into high-frequency vibrations of tens of thousands of times per second through the transducer. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy by friction, and the surface of the object to be welded is melted to complete the effective bonding. Nowadays, ultrasonic welding is widely used in many industrial production fields.Product Specification

| Ultrasonic Transducer | Ultrasonic Generator | |

| Model | H-5020-4Z | H-UW20 |

| Ultrasonic Frequency | 20KHz ± 0.5KHz | 20KHz ± 0.5KHz |

| Ultrasonic Power | 2000Watt | 2000Watt |

| Ultrasound Wave | - | Continuous / Intermittent |

| Capacitance | 11000±10%pF | |

| Resistance | ≤10Ω | |

| Storage Temperature | 75ºC | 0~40ºC |

| Working Area | -5ºC~ | -5ºC~ 40ºC |

| Size | 110*20mm | |

| Weight | 8Kg | 9Kg |

| Power Supply | - | 220V, 50/60Hz, 1 Phase |

Product Application

Because of the fast, efficient, clean and firm characteristics, ultrasonic welding has quickly won the favor of all walks of life, and is widely used in medical equipment industry, automobile industry, home appliance manufacturing industry, packaging industry, electronics industry, etc. For example, medical products such as liquid medicine filters, infusion sets, masks, oxygen bags, blood bags, automobile interior parts such as car bumpers, fuel tank caps, front and rear doors, lamps, and headlights, and household appliances that are closely related to our daily life. Plastic parts, the sealing of hoses in the packaging industry, special packing tapes, coffee cups, various lunch boxes, paper cups, etc., can achieve perfect, efficient and seamless welding with the efficient assistance of ultrasonic waves.

Product Advantage

1.Energy saving and environmental protection.2.It is more convenient than traditional welding, with fast cooling and smoke-free.3.High efficiency and low cost. Ultrasonic welding not only saves raw materials, but also improves productivity.4.Convenient completion of automatic operation.5.Good and stable welding effect. Ultrasonic can complete seamless welding and reduce the welding interface.6.The welding edges are beautiful, can complete seamless welding, and have good waterproof and sealing performance.

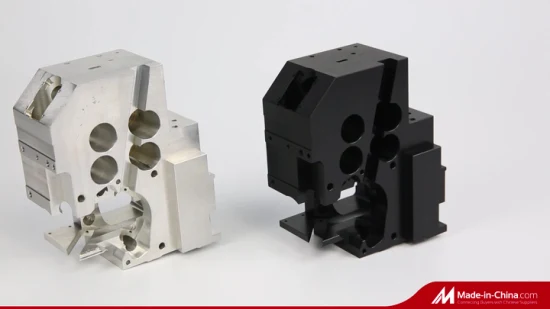

Product Details Display

Company Profile

Certifications

Feedback

Related Products

-

![20kHz Best Selling Ultrasonic Slicing Machine for Cookie Frozen Biscuit Cutting]()

20kHz Best Selling Ultrasonic Slicing Machine for Cookie Frozen Biscuit Cutting

-

![Strap up N95 Medical Face Mask Making Machine with Packing]()

Strap up N95 Medical Face Mask Making Machine with Packing

-

![High-Speed Fully Automatic Dust Surgical Medical Disposable N95 3 Ply Non Woven Face Mask Making Machine]()

High-Speed Fully Automatic Dust Surgical Medical Disposable N95 3 Ply Non Woven Face Mask Making Machine

-

![Semi-Automatic N95 Face Mask Making Machine with Built-in Nose Bridge]()

Semi-Automatic N95 Face Mask Making Machine with Built-in Nose Bridge