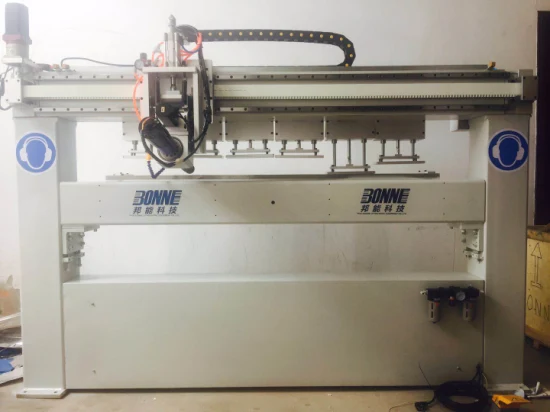

CE Certificate Ultrasonic Quilting Machine for Quilt, Sofa Matt, Baby Blanket, and Fabric Compounding

ABOUT US Wuxi Dizo ultrasonic technology co., ltd is a high tech company which specialized in technology development,man

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Customized |

| Width | 2.7m |

| Transport Package | Wooden Box |

| Specification | 5*3.2*1.8 |

| Trademark | DIZO |

| Origin | China |

| HS Code | 8515809090 |

Product Description

ABOUT US

Wuxi Dizo ultrasonic technology co., ltd is a high tech company which specialized in technology development,manufacturing and sales service of ultrasonic equipment. We improve our customer's competiation and added value by providing high quality and high performance products as well as excellent services.We adhere the business philosophy of "customer first, teamwork and Self breakthrough".With development concept of market demand as guidence, technical progress as driving force, customer satisfaction as criterion and "Start with customer demand and end with customer satisfaction", we supply best ultrasonic welding equipment and best ultrasonic welding service.Ultrasonic welding is the process of converting electric current into electric energy through ultrasonic generator.The converted high-frequency electric energy then converted into the mechanical motion of the same frequency again through the transducer, and the mechanical movement is transmitted to the welding head through a set of horn device which can change the amplitude. The vibration energy received by the welding head is transferred to the joint of the work piece to be welded. In this area, the vibration energy is converted into heat energy by friction, and the plastic is melted. Ultrasonic can be used not only to weld hard thermoplastic plastics, but also to process fabrics and films. Heat energy comes from the reciprocating movement of a work piece on another surface with a certain displacement or amplitude under a certain pressure. Once the expected welding degree is reached, the vibration will stop, and at the same time, there will still be a certain pressure applied to the two work pieces to cool and solidify the just welded parts, thus forming a close combination.Dizo ultrasonic sticks on high quality for 15 years

Technical parameters

| Model | Power supply | Effetive width | Machine size | N.W | workng environment |

| DZ-1000-S | 7KW 380V 3 phase(220v) | 1000m | 5*1.5*1.8m | 1000KG | ≤25ºC |

| DZ-1500-S | 7KW 380V 3 phase(220v) | 1500m | 5*2*1.8m | 1500KG | ≤25ºC |

| DZ-1800-S | 8KW 380V 3 phase(220v) | 1800m | 5*2.3*1.8m | 1800KG | ≤25ºC |

| DZ-2300-S | 8KW 380V 3 phase(220v) | 2300m | 5*2.8*1.8m | 2300KG | ≤25ºC |

| DZ-2700-S | 9KW 380V 3 phase(220v) | 2700m | 5*3.2*1.8m | 2700KG | ≤25ºC |

| DZ-3000-S | 9KW 380V 3 phase(220v) | 3000m | 5*3.5*1.8m | 3000KG | ≤25ºC |

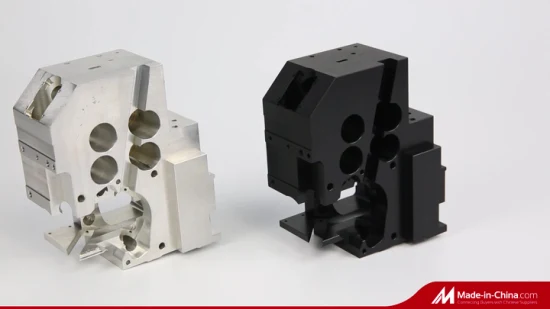

Basic components

1.Adopting the latest ultrasonic control box with strong and stable power.It is suitable for long- time and continuous work.Buiilt-in PC chip and multi-circuit ultrasonic protection system to make the main machine run safely and steadly.2.Structure of machine1)pattern press compound machine2)Ultrasonic control cabinet,3)End products rolling machine.

Characteristics

No thread and needie,beautiful outer appearance of the products,all kinds of dimensions to keep up with the popularity,changing the pattems according to the needs,strong seat and high production efficiency.

Application cases

Producting the compounding of spout gumcotton,non-woven fabrics and needle cotton with chemical fiber fabrica,artificial leather products.The patterns can be designed as you pleasure.It is applied to the production of fabrics for garment,bed spread,pillow,sofa and indoor decorations.

Other Textile Machines

FAQ

1.

Q:Are you a manufacturer?

A: Yes. We are a manufacturer speclialized in producing plastic welding equipments and solutions.2

Q: How long is your after sale service?

A: One year free maintenance, all lifetime maintenance service from us.3

Q:Can you provide customized machines?

A:Based on 15 years manufacturing foundation, we are good at product design and customization.4.

Q:When will I get feedback for my enquiry?

A: Experienced staffs answer all your questions in fluent English within 24 working hours5.

Q:How do you control the quality?

A:We assure our product of quality, with innovative design, industrial grade quality circuit board, advanced production line and strict quality control procedures. Dizo sticks on making ONLY high quality machines and which already brought us lots of positive feedback & repeat orders.