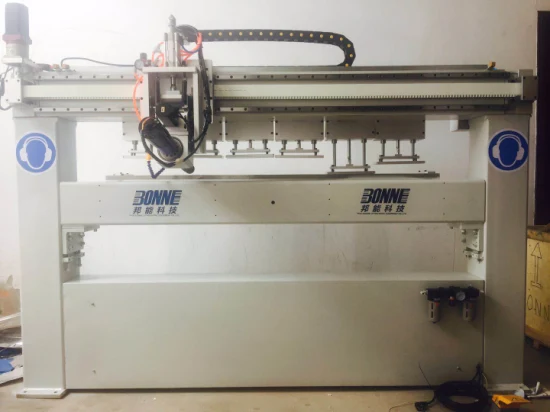

Factory N95 Mask Production Line Mask Making Machine

Factory Face Mask automatic semi automatic N95 mask making machine Process: Automatic →Nose bridge Bar→Ear loop Welding

Send your inquiryDESCRIPTION

Basic Info

| Application | N95 Mask Making |

| Automatic Grade | Semi-Automatic |

| Certification | CE, ISO9001: 2000 |

| Customized | Customized |

| Condition | New |

| Key Word 1 | Face Mask Machine |

| Key Word 2 | Face Mask Making Machine |

| Key Word 3 | N95 Mask Making Machine |

| Transport Package | Wooden Cases Packing |

| Specification | 9500(L)*1500(W)*1800(H)mm |

| Trademark | RX |

| Origin | Henan |

| Production Capacity | 50 Sets Per Month |

Product Description

Factory Face Mask automatic semi automatic N95 mask making machineProcess: Automatic →Nose bridge Bar→Ear loop Welding →Pressing →UltrasonicFusion→Forming and Cutting→Collecting Type of Production:1. KN95/N95 mask sample (4 layers) as below photos2. Mask layers are applicable for 4 or 6 layers.3. Nose piece width: ≤5mm Length: ≤ 91mm4. Material width: 260mm5. If the width of nose piece has specific requirement, it is necessary to customize the roller mold Equipment installation and configuration requirements:1) equipment size: 9000mm(L)×1600mm(W)×2100mm(H);2) appearance color: sheet metal RAL5012, in accordance with this standard without special instructions;3) equipment weight: ≤2500kg, ground load ≤500KG/m2;4) working power supply: three-phase four-wire system 380V, 50HZ;5) rated power: 12KW;6) compressed air: 0.5 ~ 0.7mpa, with a flow of about 550L/min;7) operating environment: temperature 10-35 ºC, humidity 10-60%HR, no combustible, corrosive gases, no dust (cleanliness is not lower than 100,000).8) operator: 1 person9) production specifications: built-in nose bridge strip KN95, the default size is as follows: see the picture on the left and the picture on the right; In the absence of special instructions, according to this standard; The main structure of the equipment:

| Number | Part name | Quantity |

| 1 | Melt spraying cloth/non-woven cloth/heat sealing cotton, etc,are arranged on the material shelf | 6 sets |

| 2 | Nose bridge strip unwinding mechanism | 1 set |

| 3 | Nose bridge strip straightening mechanism | 1 set |

| 4 | Nose bridge strip drive/cutting and conveying mechanism | 1 set |

| 5 | Printing mechanism | 2 sets |

| 6 | Tooth die welding mechanism | 1 set |

| 7 | Tooth die welding power mechanism | 1 set |

| 8 | Ear belt feeding and welding mechanism, left and right ear belt each set | 2 sets |

| 9 | Fabric folding mechanism in half | 1 set |

| 10 | Cloth folding traction power mechanism | 1 set |

| 11 | Cloth fine-tuning mechanism | 1 set |

| 12 | Sealing edge welding mechanism | 1 set |

| 13 | Sealing edge welding traction power mechanism | 1 set |

| 14 | Cutting mechanism after molding | 1 set |

| 15 | Finished product discharging conveying mechanism | 1 set |

| 16 | Operating system | 1 set |

| 17 | Operation panel | 1 set |

| Equipment | KN95/N95 mask production line |

| Specification | 9500(L)×1500(W)×1800(H)mm |

| Operation environment | Temperature: 5~45ºC Humidity: below 80% RH |

| Rated voltage | 220V,50HZ Can be Specified. |

| Rated Pressure | 4.0~7.0kgf/cm2 |

| Qualification rate | Above 96%, problems caused by the product material itself excluded |

| Theoretical Efficiency | 30-35pcs/min |

| Number of operator | 1P/10 set |

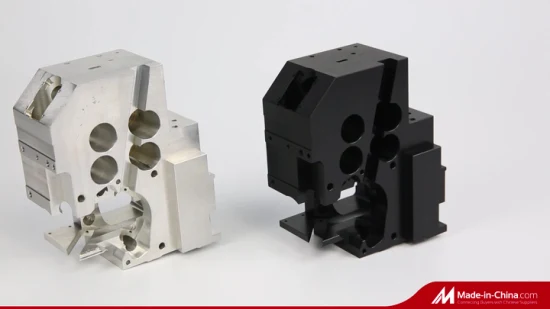

| Main components | Airtac, Yhda/Misumi, Omron/SICK, KEYENCE |

| Safety | Meet the machinery national standard |

Related Products

-

![Ultrasonic Lace Making Sewing Machine for Non Woven Bag]()

Ultrasonic Lace Making Sewing Machine for Non Woven Bag

-

![Customized High Quality Industrial Ultrasonic Welding Machine for Quilting and Textile]()

Customized High Quality Industrial Ultrasonic Welding Machine for Quilting and Textile

-

![Computer PVC Tube Tape Nylon Leather Belt Cutter Machine Plastic Pet Film Roll to Sheet Cutting Machine]()

Computer PVC Tube Tape Nylon Leather Belt Cutter Machine Plastic Pet Film Roll to Sheet Cutting Machine

-

![Manufacture Comforter Carding Fiber Opening Ultrasonic Quilting Machine with CE]()

Manufacture Comforter Carding Fiber Opening Ultrasonic Quilting Machine with CE